To fill the gap, I set the edge up level and clamped the part to hold it . Then I made a small dam about 1/8″ high for each end out of folded masking tape. Finally, I put a masking tape fence along each side of the edge. I mixed up 1 pump (about 1 ounce) of epoxy and poured it in between the fences. It flowed into the gap a bubbles began to come up. To speed the process, I pinched the sides of the gap with pliers to squeeze the air out, releasing sucked the epoxy in. Repeat as desired.

When the gap was filled with epoxy, I put C-clamps (G-clamps in some parts of the world) on wherever I could see that it squeezed the gap closed. This caused the excess to squeeze out but the fences and the dams kept the excess from flowing down the sides. (The drip you see in the picture is from the other edge before I learned the part about the dams at the ends.) When the epoxy was set, removed the clamps and tape. Sand the excess hardened epoxy off. The gap is filled.

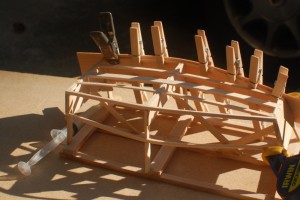

Model: Optimist Pram

. Setting up the actual boat frames was complicated. If you were doing it full size, you could use a tape measure and level or plumb-bob. As it was getting the measurements set up in the middle-of-thin-air took some clever clamp-measure-move-reclamp action to get it just right over several days as I had to wait for the glue to dry to do the next frame. I think that the center bulkhead is 1/16″ off-square which would be 1/2″ in full size.

. Setting up the actual boat frames was complicated. If you were doing it full size, you could use a tape measure and level or plumb-bob. As it was getting the measurements set up in the middle-of-thin-air took some clever clamp-measure-move-reclamp action to get it just right over several days as I had to wait for the glue to dry to do the next frame. I think that the center bulkhead is 1/16″ off-square which would be 1/2″ in full size.

Once the frames were set up, the corners were notched and the chines and keels were set in. A little sanding to shape.

The rudder and centerboard were next along with the mast, boom, and sprit. Finish is varnish.

The sail was laid out with a program named Sailcut. It neatly lays out panels perpendicular to the leech givin a very realistic appearance to the modeled sail. The “eyelets” are dots of gold sparkle-pen ink.

What’s the diff?

My problem was that my revised version of the Java program did not work as expected. While I believed that I had changed nothing but comments, the results were not the same. What had I changed?

“Oh, that’s easy” says I, “I’ll just diff the files and see what changed”. Well according to diff, EVERYTHING had changed. I used the regular options like -w, and -E, and -d, and -B and still no improvement.

“Duh”, he says, “it’s the encoding”. What is the diff option to compare two texts with different encoding? The short answer seems to be that there is no option.

But where there’s a will, there’s a way, particularly with Linux (and Unix). In Linux use the iconv command to do the conversion and pipe the output to diff for the compare.

If you do not know iconv, the short form is:

iconv -f from-file-encoding -t to-file-encoding from-file-name

Output to stdout.

Pipe it to diff and tell diff to pick up the input from the pipe with a dash – .

If you do not know the encoding of the files, use the file command to show you the encoding.

To find out if the encoding is supported (and spelled correctly), use

iconv -l

for a list of supported encodings.

The answer to the original question looks like:

iconv -f ISO-8859-1 -t UTF-8 ../x3-2.14/x3navaldv0.2.14/java/bateau/Bateau.java | diff -w - java/bateau/Bateau.java

I had changed only comments. Compiler difference? Compiler option difference?

Sailboats – Then and Now

Long ago and far away, I was lucky enough to go to a boy’s camp near Charlevoix, Michigan. Camp Charlevoix. At Camp Charlevoix, I was lucky to sail what is still one of my favorite sailboats. The Snipe class. The boats that I sailed had no sail numbers I remember. Web surfing I find Snipe 2457, an early number. The picture is full color. My birthday card arrived from aunt. Snipe 2740 with my Uncle Leonard sailing and my mother crew. My understanding is that Uncle Leonard built the boat while in high school in consultation with Clark Mills who was already building similar boats in Clearwater, Florida. I checked the model on the mantel, Snipe 4270. A longer story, maybe not for here. If you can only have one boat, it should be a Snipe.